- Home

- Products

-

- TH1950 High Precision Multi-function Calibrator

- TD1880 Precision Multi-function Calibrator

- TD1870 Multi-function Calibrator

- TD1860 Multi-function Calibrator

- TD1855 Multi-function Calibrator

- TD1858 Portable Multi-function Calibrator

- TD1850 Multi-function Calibrator

- TD1500 High-precision DC Standard Source

- TD1020 Current Coil

- TD1000 Clamp Meters Calibration Device

- TD1050 Clamp Meters calibration device

-

-

- TK4830 Portable Tester for AC DC EV Chargers

- TD1320 Portable Tester for DC EV Chargers

- TD1330 Portable Tester for AC EV Chargers

- TK4850E DC EV Charging Station Testing Device

- TK4860E AC EV Charging Station Testing Device

- TK4800 Calibration Device for Portable Tester for EV Chargers

- TK4710 DC Adjustable Resistance Load

- TK4720 AC Adjustable Resistance Load

- TK4730 AC/DC Portable Resistive Load

- TK4960 DC Charging-power Calibration Adapter

- TK4965 AC Charging-power Calibration Adapter

-

-

- TH0100/TH0104 Advanced DC Voltage Reference Standard

- TH0110 Programmable DC Voltage Reference Standard

- TH0150 Wideband Voltage Divider

- TH0170 Precision DC High Voltage Divider

- TH0180 Precision AC/DC High Voltage Divider

- TH0190 Handheld Precision Voltmeter

- TH0195 AC/DC Voltage Measuring Standard

- TH0400 Precision Coaxial Current Shunt

- TH0410 High Frequency Coaxial Shunt

- TH0420 Reference Coaxial Current Shunt

- TH0460 Coaxial Shunt Multiplexing Unit

- TH0470 Precision Wideband Buffer

- TH0475 High Frequency Voltage Isolation Buffer

- TH0480 Resistance Time Constant Standard

- TH0490 Bisector Current Ratio Standard

- TH0500 Precision Current Transformer

- TH0540 Precision Current Transducer

- TH0600 Precision AC Current Transformer

- TH0680 Multiplexing I/V Selection Units

- TH0690 Current Transducer Integrated Measurement Analyzer

- TH0780 Multiplexing V/V Selection Units

- TH1000 Ultra-stable Precision Current Source

- TH1200 Nanovoltmeters Calibrator

- TH2000 Vector Voltage Analyzer

-

-

- TH0200 Standard Resistance Measuring Device

- TH0210 Standard Resistance Measuring Device

- TH0240 Standard Resistance Multiplexer

- TH0260 Precision Resistance Analyzer

- TH0300 High Power Resistance Standard

- TH0310 Resistance Standard

- TH0320 Reference Resistance Standard

- TH0330 Ultra-Stable Resistance Standard

- TH0340 AC Resistance Standard

- TH0350 DC Bridges Calibrator

- TH0360 High-precision DC Resistance Meter Calibrator

- TD1400 Loop Resistance Tester

- TD1450 Analog Standard Resistor

- TD1470 Single and Double Arm Bridge Calibration Device

- TD1540 DC Shunt Verification Device

- TD2100 DC Shunt Verification Device

-

-

- TH0520 Precision Current & Voltage Measurement Standard

- TH0530 Precision Through-core Ammeter

- TH0630 Precision Through-core AC Ammeter

- TA1000 Transconductance Current Standard Source

- TD1090 Through-core AC I/V Transformer

- TA1200 High Frequency Transconductance Amplifier

- TH1300 DC High Current Sensor & Shunt Calibration System

- TA1300 AC Current Standard Source

- TA1500 AC/DC Current Standard Source

- TD2010 DC High Current Standard Source

- TA1100 Transconductance Amplifier

-

-

- TH3000 AC/ DC Power & Energy Measurement Standard

- TH3900 DC Power & Energy Reference Standard

- TD1300 Precision DC Standard Meter

- TD1310 Precision AC/DC Standard Meter

- TD1545 DC Energy Meters Verification Device

- TD1548 DC Energy Meter Comprehensive Verification Device

- TD1550 DC Energy Meters Verification Device

- TD1570 Indirect Connected DC Energy Meters Verification Device

- TD1575 DC Energy Meters Verification Device

- TD1580 DC Energy Meters Testing Device

-

-

-

- TK3300 Installed Three-Phase Standard Energy Meter

- TD3310 Three-phase Multi-function Standard Meter

- TD3110 Single-Phase Multi-Function Standard Meter

- TK3100 Installed Single-Phase Standard Energy Meter

- TD3300 Three Phase Multi-function Standard Meter

- TD3100 Single-phase Multi-function Standard Meter

- TD3810 Three-phase Energy Device Field Testing System

- TD3250 Portable Three-phase Energy Meter Tester

-

-

- TH3600 Broadband Low Current Standard Power Source

- TD3500 Single-phase Energy Meters Verification Device

- TD3750 AC Power Detection Device for Electromagnetic Compatibility Testing

- TD3600 Three-phase Energy Meters Verification Device

- TD3650 Three-phase Energy Meters Verification Device

- TD3610 Three-phase Standard Energy Meters Verification Device

- TD3760 Complex Waveform Testing Device

- TD3900 High-precision Three-phase Power Source

- TD4550 Portable Tester for Three-phase Energy Meter

- TD4100 Portable Tester for Three-phase and DC Meters

- TD4200 Testing Device for Three-phase and DC Meters

- TD4500 PortableTester for AC Sampling Devices and Transmitters

- TD4510 Portable Tester for Three-phase and DC Meters

- TD4520 Portable Tester for Three-phase and DC Meters

- TD3550 Single-phase Energy Meters Verification Device

- TD4530 Portable Tester for Three-phase and DC Meters

- TD3700 Energy Meter Power Frequency Magnetic Field Test Device

- TD3710 Energy Meter Constant Magnetic Field Test Device

- TD3720 Load Current Rapid Change Test Device

- TD3730 Energy Meter Power Frequency Strong Magnetic Field Test Device

- TD3740 Energy Meter Durability Test Device

-

-

- TD1210 Verification Device for Leakage Current Tester

- TD1210A Leakage Current Tester Verification Device

- TD1220 Verification Device for DC High Voltage & High Value Resistor

- TD1230 Verification Device for Withstanding Voltage Tester

- TD1240 Verification Load Bank for Withstanding Voltage Testers

- TD1250 Verification Device for Earth Continuity Testers

-

-

- TD2650 Precision AC/DC High Voltage Meter

- TD5400 High Voltage Wideband Electric Energy Measurement Test Device

- TD5560 Three-Phase High Voltage Wideband Power Standard Device

- TD5610 Three-Phase High Voltage Wideband Power Standard Meter

- TD2400 AC High Voltage Standard Source

- TD2410 High Voltage Meters Calibration Device

- TD2500 DC High Voltage Standard Source

- TD2550 Non-touch Static Voltmeters Calibration Device

- TD2600 Precision DC High Voltage Meter

-

-

- TD7500 Process Signal Calibrator

- TD7600 Precision Process Calibrator

- TI1000 Precision AC/DC Voltage Calibrator

- TI1100 Precision AC/DC Current Calibrator

- TI1200 Precision DC Resistance Calibrator

- TI2000 DC High Current Standard Source

- TI2100 High-stable DC High Current Standard Source

- TI5000 DC Current Sensor Testing Device

- TI5100 DC High Voltage Sensor Testing Device

- TI5300 AC DC Current Sensor Testing Device

- TI5800 Sensor Power Supply and Output Tester

- TK2600 Pulse Voltage Source

- TK2650 Pulse Current Source

- TK6500 Electric Welding Machine AC/DC Power Calibrator

- TK6700 Electric Welding Machine Electric Power Parameters Comprehensive Calibrat

- TK6400 Load Box for Electric Welding Machine Calibration

- TP1000 Surface Resistance Tester

- TP2000 Handheld Temperature Humidity Meter

- TD6600 Relay Protection Tester Verification Device

- TK6800 Transformer Comprehensive Characteristic Tester Calibration Device

- TK8100 Calibrator for Low-voltage Circuit Breakers

- TD1170 Zinc Oxide Lightning Arrester Tester Calibration Device

- TD2700 Multi-Function Time Calibrator

-

-

-

- TM6140B Precision Magnetometer

- TM7600 Digital Integration Flux Meter

- TM7900 Precision Volt-second Generator For Flux Meter Calibration

- TM9000 Calibration System for Magnetometers

- TM9100 Precision Magnetometer Calibration Device

- TM9200 Alternating Magnetometer Calibration Device

- TM9300 Fluxgate Magnetometer Calibration Device

- TM5100 Handheld Tesla Meter

- TM5100A Handheld AC Magnetometer

- TM5120B Handheld Tesla Meter

- TM5340B Handheld Triaxial Tesla Meter

- TM6100 Gauss Meter

- TM6160B AC/DC Tesla Meter

- TM4100B Handheld Fluxgate Magnetometer

- TM4300B Handheld Triaxial Fluxgate Magnetometer

- TM4830B Fluxgate Magnetometer

- TM7100 Handheld Flux Meter

- TM7500 Flux Meter

- TH8010 Electrical Steel Magnetic Measurement Device Calibration System

- TH8020 Soft Magnetic Material DC Magnetic Meter Calibration System

- TH8030 Calibration System for Permanent Magnet Magnetic Measuring Instrument

- TH8100 Magnetic Field Coil Comprehensive Calibration Device

- TM1100/1110/1130 Hall Probe

- TM1200/1230 Fluxgate Probe

- TM2000/2030 Precision Current Source

- TM2300/TM2330 Helmholtz Coil

- TM2400 Solenoid

-

-

- TD81Series AC Magnetic Properties Measuring System for Soft Magnetic Materials

- TD8160 Magnetic Properties Measuring System for Single Sheet Amorphous

- TK8600 Metal Magnetic Powder Core Magnetic Properties Testing Device

- TS4000 DC Magnetic Properties Measuring System for Soft Magnetic Materials

- TS7710 Type A / B Permeameter

- TS7750 Solenoid

- TS7900 Multi-channel Permeability Meter Selector

- TS7910 Wiring Converter for Electrical Steel Magnetic Measuring Instrument

- TY1000 Magnetic Properties Measuring System for Hard Magnetic Materials

- TY1100 Magnetic Properties Measuring System for Hard Magnetic Materials

- TY1500 Electromagnet

- TY1550 Pole of Electromagnet

- TY1700 Search Coils

- TY1900 Specimen Heating Device

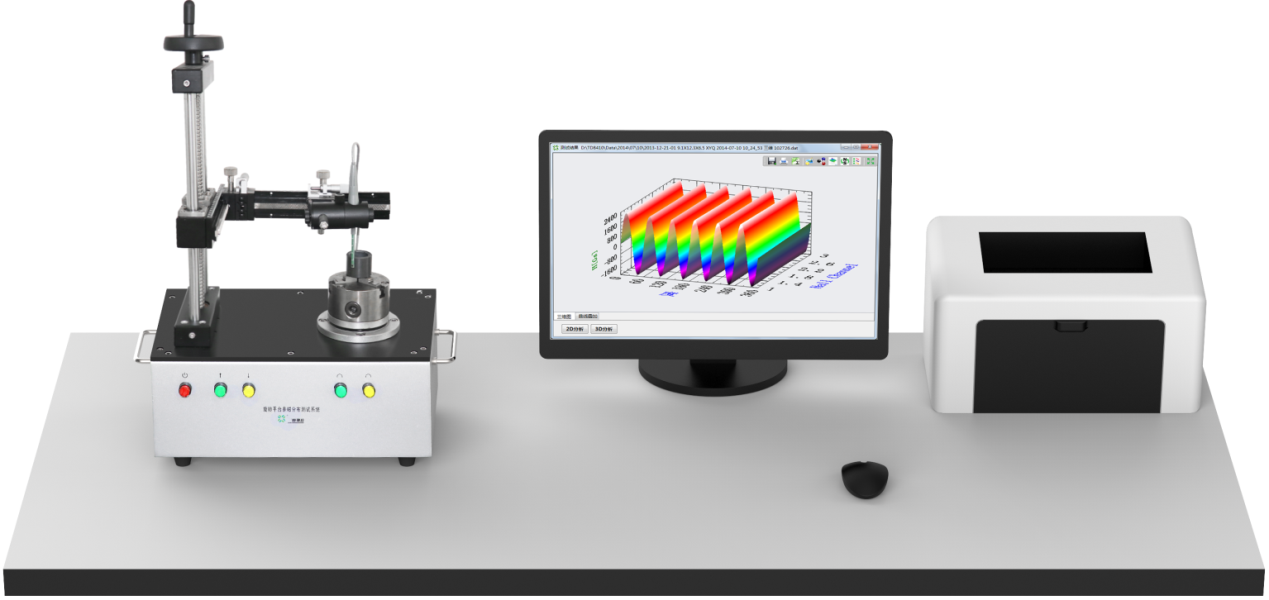

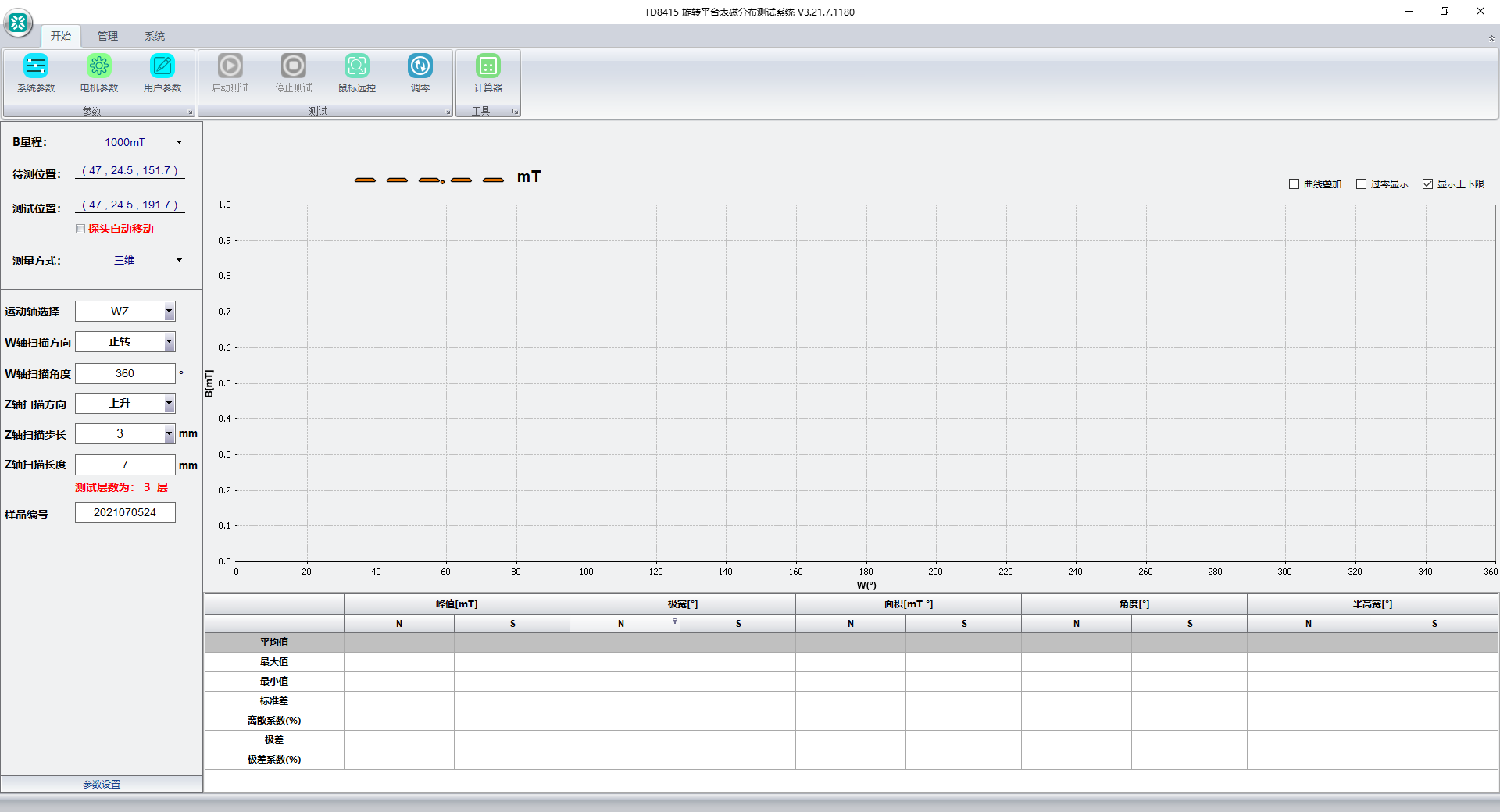

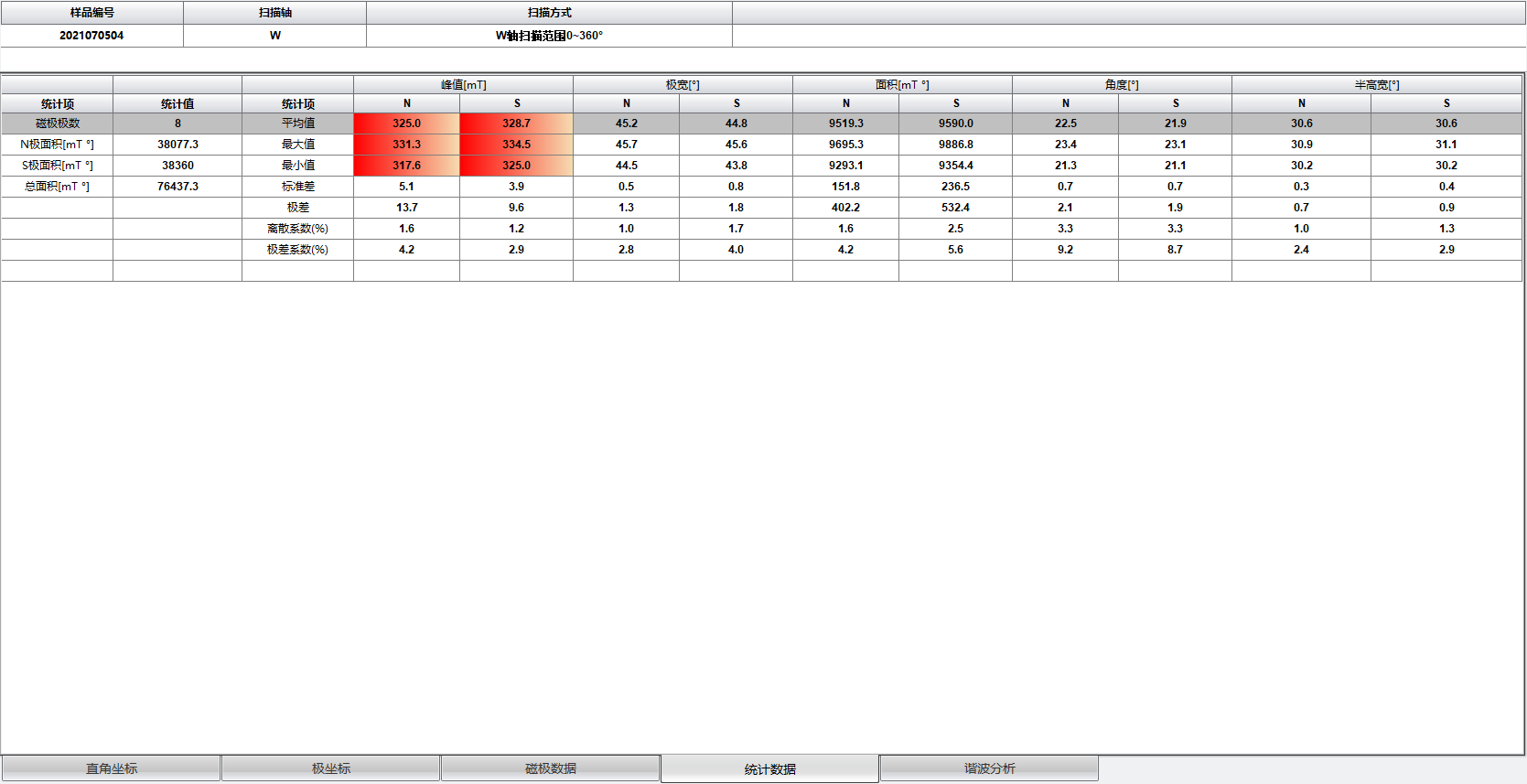

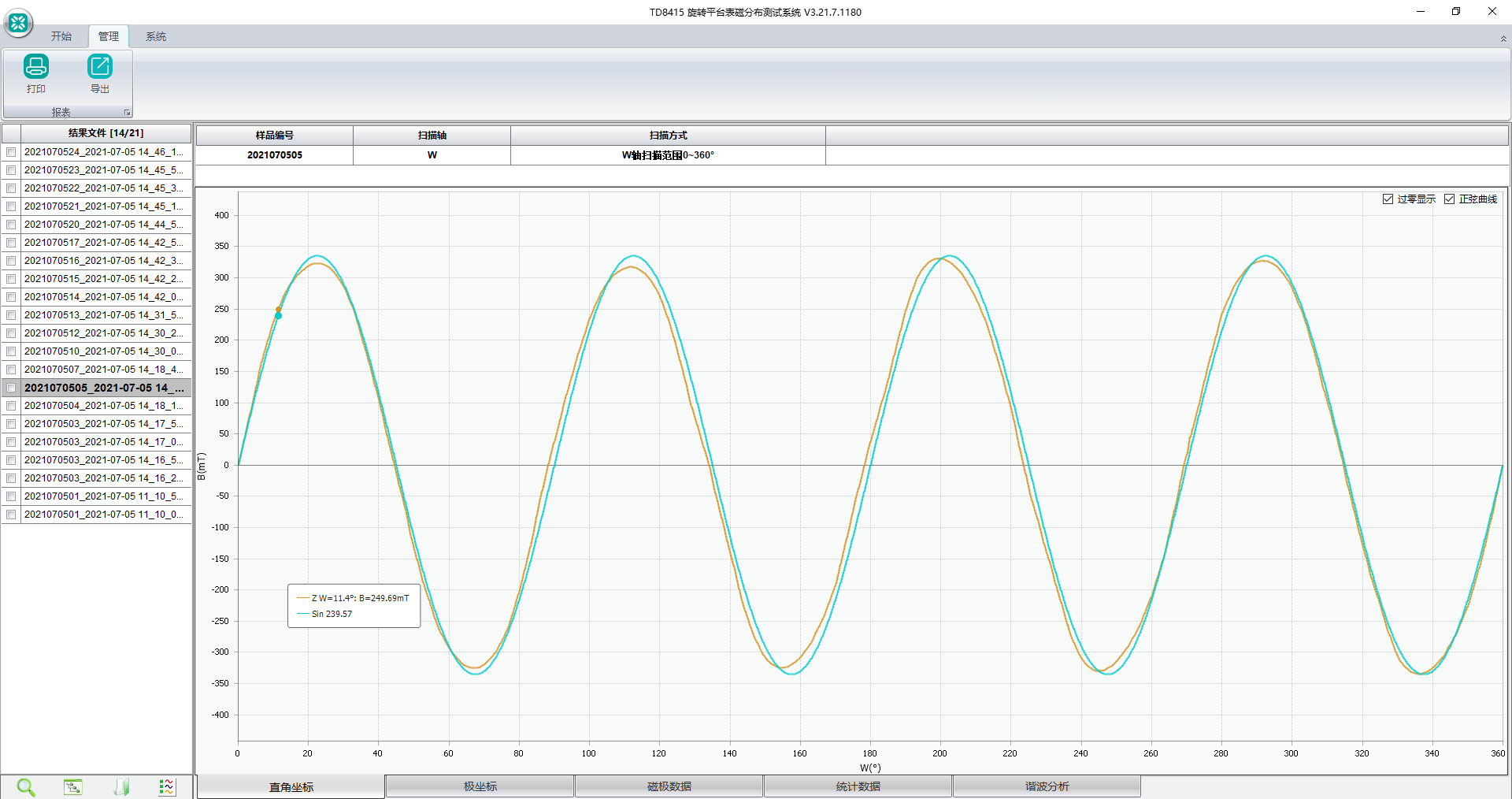

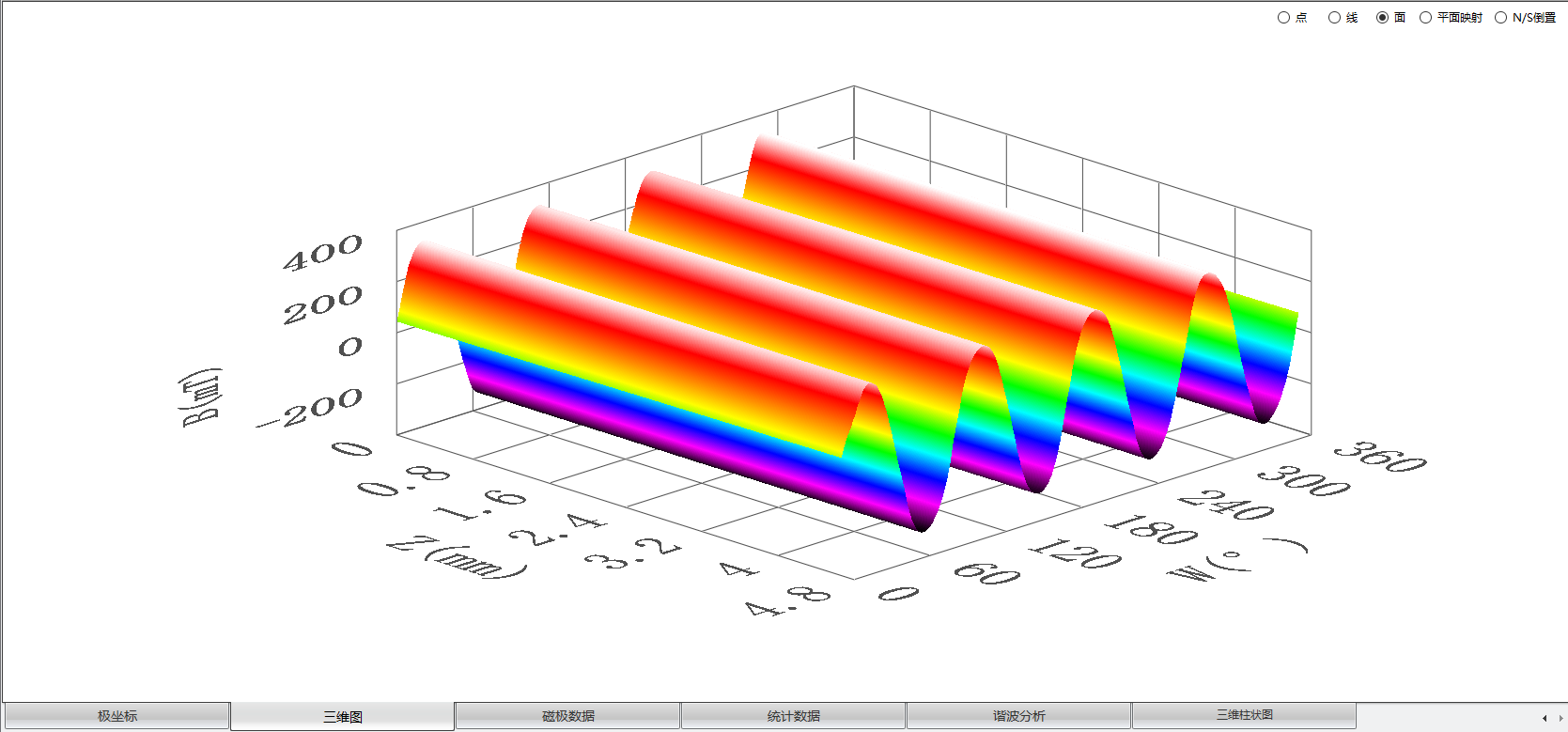

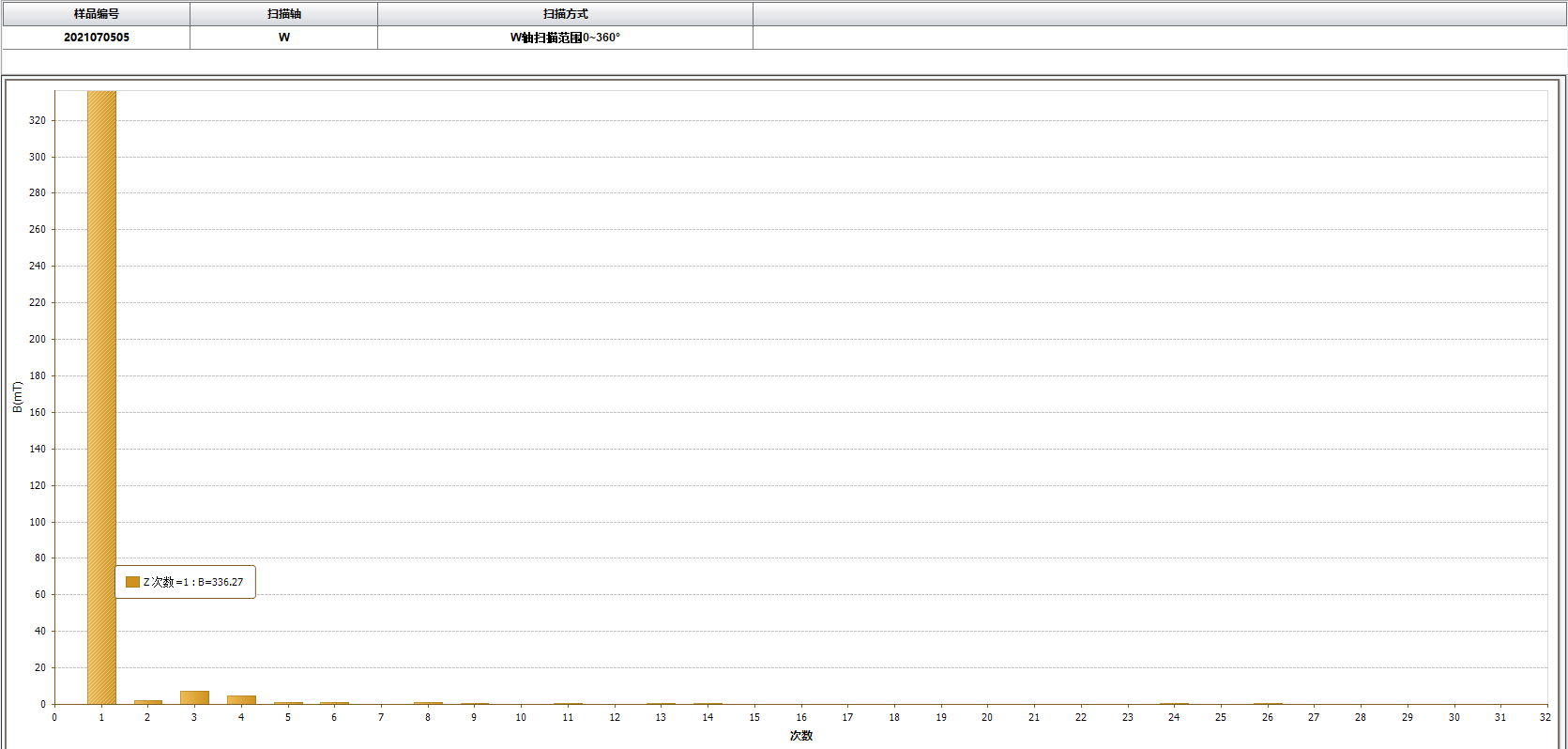

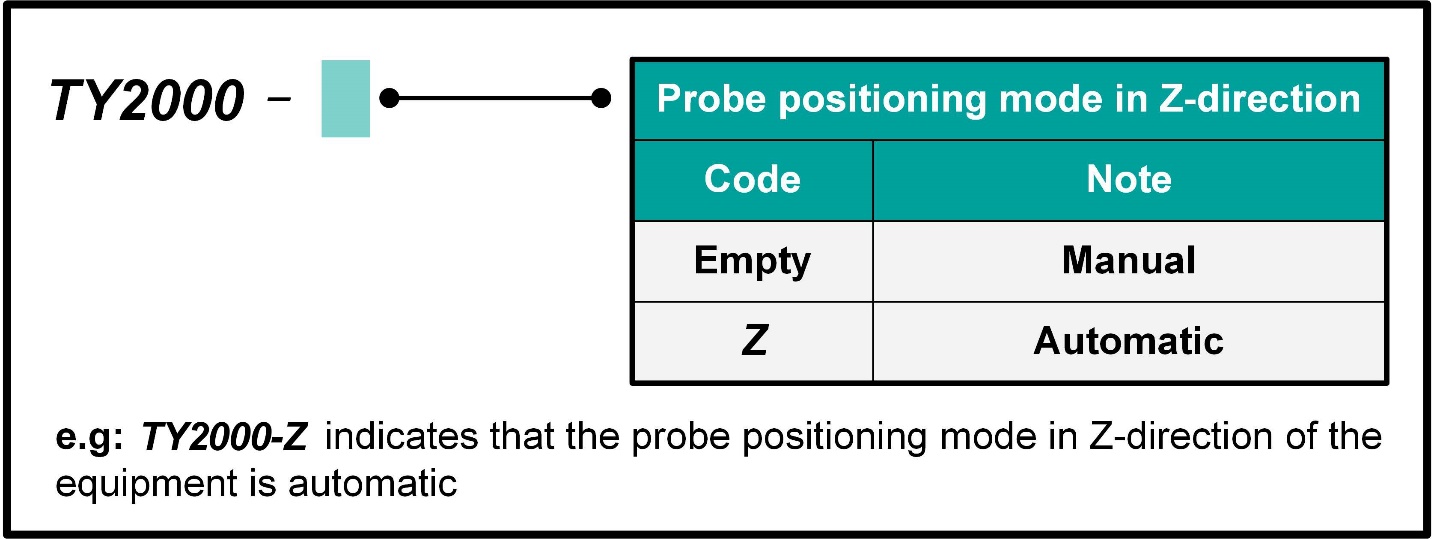

- TY2000 Surface Magnetic Field Automatic Testing System

- TY2100 Surface Magnetic Field Automatic Testing System

- TY2200 Surface Magnetic Distribution Automatic Testing Device

- TY2500 Multi-Probe Surface Magnetic Distribution Test Device

- TY3000 Magnetic Moment Tester

- TY3100 High-precision Magnetic Moment Tester

- TY3300 Magnetic Declination Tester

- TY3500 Pipe Inner Wall Oxide Scale Tester

- TY4810 Magnetic Moment Measurement Coil

-

-

- TD9100 Online Testing System for Magnetic Properties of Silicon Strip

- TS1000 DC Magnetic Properties Measuring System for Electrical Steel

- TS1020 DC Magnetic Properties Measuring System for Yoke Steel

- TS1100 AC Magnetic Properties Measuring System for Electrical Steel

- TS1200 AC Magnetic Properties Measuring System for Electrical Steel

- TS1300 AC/DC Magnetic Properties Measuring System for Electrical Steel

- TS2000 Rotational Magnetic Properties Measuring System for Electrical Steel

- TS2500 Magnetic Properties Measuring System for Electrical Steel Cores

- TS2600 Iron loss Fast Tester for Electrical Steel Sheets

- TS3000 Magnetic Properties Multifunction Measuring System for Electrical Steel

- TS3200 Electrical Steel Sheet Magnetic Properties Automatic Measurement System

- TS3210 Automatic Measurement System for Magnetic Properties of Electrical Steel

- TS1700 Surface Insulation Resistance Measuring System for Electrical Steel

- TS1710 Surface Insulation Resistance Automatic Measuring System for Electrical

- TS1780 Stacking Factor Measuring System for Electrical Steel Sheets

- TS1800 Bending Testing System for Electrical Steel Sheets

- TS1810 Bending Automatic Testing System for Electrical Steel Sheets

- TS7000/TS7010/TS7020/TS7100 Epstein Frame

- TS7500/TS7510 Single Sheet Tester

- TS1770 Silicon Steel Sheet Coating Adhesion Tester

- TS3300 Electrical Steel Magnetostriction Measurement Device

-

-

- News

- Solution

-

- Download

- About Us

- Contact Us